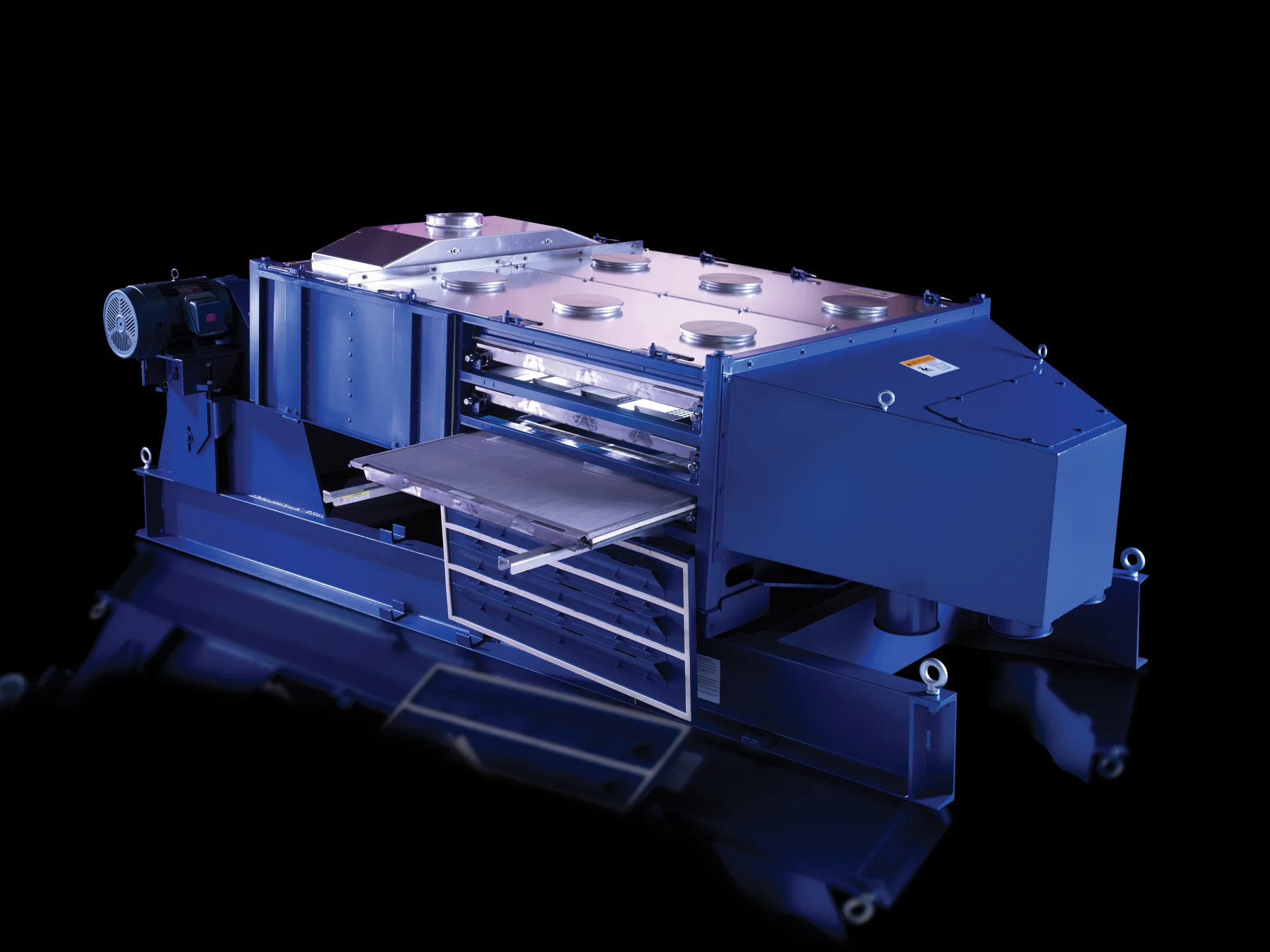

iBulk Apex Dry Separation Screener

The same efficient screening you have come to expect redesigned to be maintained by only one person in less time. The savings speak for themselves.

iBulk Apex Dry Separation Screeners are designed for efficient performance, quick and easy maintenance and cleaning. In addition, this provides increased process "uptime" within your production line. The ergonomic design enables the dry screener to be maintained by just one person!

Rotex Screeners are self-contained production screening machines for separating dry materials according to particle size.

iBulk Apex Dry Separation Screeners have a unique gyratory-reciprocating motion of the near-horizontal screen surface, combined with a positive screen mesh cleaning system.

Unique Gyratory-reciprocating Motion

The Unique Gyratory-reciprocating motion rapidly distributes, stratifies and separates.

This motion imparts a combination of actions to the material as it passes along the screen surface. It begins with a horizontal circular motion at the feed end, gradually diminishing along the length of the machine to an elliptical path, and finally to an approximate straight-line motion at the discharge end. There is no vertical component to this motion – thus keeping the material in constant contact with the screen surface.

Distributes: CIRCULAR MOTION AT FEED END

The gyratory motion at the feed end of the machine immediately spreads the material across the full width of the screen surface to maximise screen utilisation – even though the feed is from a single point?

At the same time, this motion stratifies the material, causing the fines to sink down against the screen surface. The particles that are appreciably smaller than the openings quickly pass through at this part of the screen.

Stratifies: CHANGING TO ELLIPTICAL MOTION AT CENTRE

As the circular motion diminishes into an elliptical path, the gentle near-horizontal motion causes the fine particles closer in size to the screen mesh – the near-size particles – to fall through the mesh openings.

Separates: STRAIGHT-LINE MOTION AT DISCHARGE END

The nearly linear reciprocating motion at the discharge end of the iBulk Rotex Screener removes those particles closest in size to the mesh openings while gently conveying the oversize material off the screen. In addition, the unique iBulk Rotex ability to advance or retard material flow at the discharge

Installation

FLOOR MOUNTING

The low transmitted forces of the Apex counterbalanced drive allow the unit to be floor mounted in properly designed structures where some other types of equipment cannot. Mounting may be directly on the floor or on an elevated structural steel framework, the elevated position permitting drums or other equipment to be located under the machine. iBulk Apex application engineers can recommend a stand for any specific dry screening application.

CABLE SUSPENSION

Apex Dry Separation Screeners can be cable-suspended from the four corners of the machine, thereby isolating out-of-balance screening forces from the surrounding structure. Accurate counterbalancing of the iBulk Apex Screener makes this installation option possible. If the existing overhead structure is not suitable for cable suspension, or is structurally unable to support the cable-suspended unit, the Apex Screener can be suspended from a floor-mounted cable support stand. As with conventional cable suspension, this option effectively isolates the horizontal out-of-balance screening forces, helping to minimise costs for new structures as well as permitting the use of older structures which might not otherwise support cable-suspended equipment.

Advantages

The ergonomic design enables the dry screener to be maintained by just one person!

Quick and easy screen inspection, screen changes, and cleaning by one person!

Screens can be changed in 80% less time!

Inspection of all screens (8 in the 3m2 machine) in less than 10 minutes!

Operator lifted components weigh no more than 18 kg.

Screen panels weigh only 2.5 kg.

The Apex dry separation screener retains the gyratory motion and efficient processing characteristics of the Rotex Gyratory Screener

Applications and Industries

Agriculture

Chemical

Minerals

Food

Recycle

Plastic