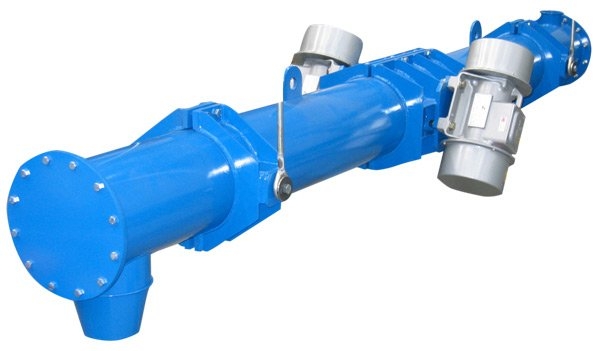

iDDT Tubular Feeders

iBulk Tubular Feeders are the ideal solution when transferring material between different stages of the production process.

They require minimal maintenance and can run in fairly harsh conditions.

Advantages

Tubular feeders are fully enclosed and dust tight

Require less maintenance than a conventional feeder

No moving parts

Minimal space required

Continuous heavy duty operation

Provides an economical link in the handling of a wide range of bulk materials from?storage piles, hoppers, bins and silos

Accurately places feed material into or onto other processing equipment at a predetermined capacity and orientation

Capable of variable speeds where required

Do not require special foundations

Applications and Industries

Typical process equipment to which the feeders can be applied for feeding controlled tonnages from hoppers are:

Belt conveyors

Vibrating screens

Crushers

Weigh hoppers

Elevators

Ball and tube mills

Mixers

Packing devices

Kilns

Installation

Tubular Feeders may be suspended on rubber compression springs. Alternatively Tubular Feeders can be mounted on rubber springs and for heavy duty or high temperature applications on steel coil springs. This makes them freely vibrating units transmitting minimal vibration to surrounding structures. They do not require special foundations.